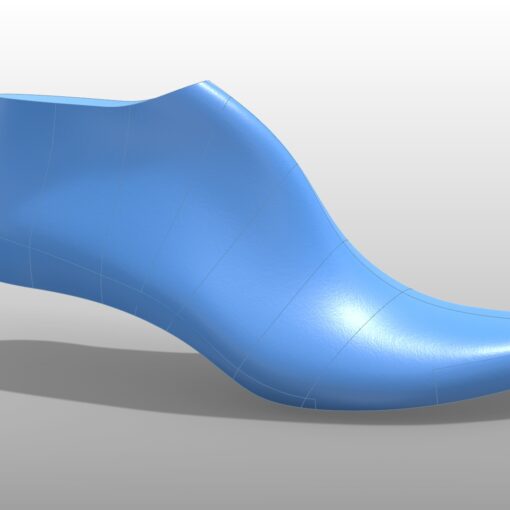

In addition to digital 3D models of shoe lasts, actual physical 3D printed shoe lasts can now be purchased here on 3DShoemaker.com. This is just a quick update to explain a few of the different ways this can be done and talk a bit about 3D printed shoe lasts in general.

There are essentially three ways you can order 3D printed shoe lasts from 3DShoemaker. First, you can select any in-house shoe last design, which are highly customizable. Second, on the Services page, you can request to have a design developed. And then it can be ordered in any size and customized same as if it were an in-house design. Third, you can submit your own design to get 3D printed. Your design could come from the 3DShoemaker plugin for Rhinoceros 3D or a 3rd party source, even just an stl file you might have handy.

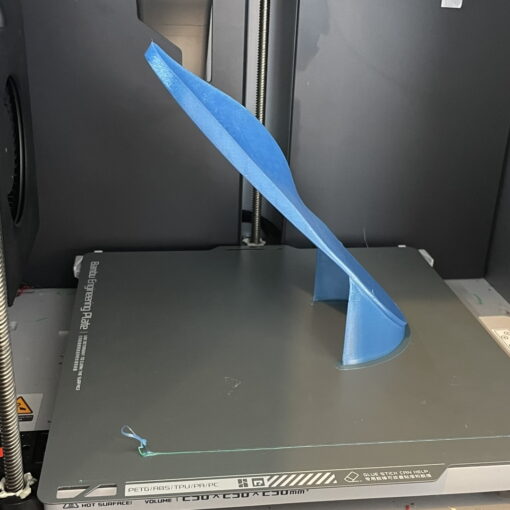

When you order 3D printed shoe lasts from 3DShoemaker, they will be printed with PETG filament. This material is somewhat harder than conventional high density polyethylene, so nailing can be a bit harder. But with thin and sharp nails, it is not an issue. The wall thickness used is 5mm which is more than enough for nailing and results in a light yet strong shoe last.

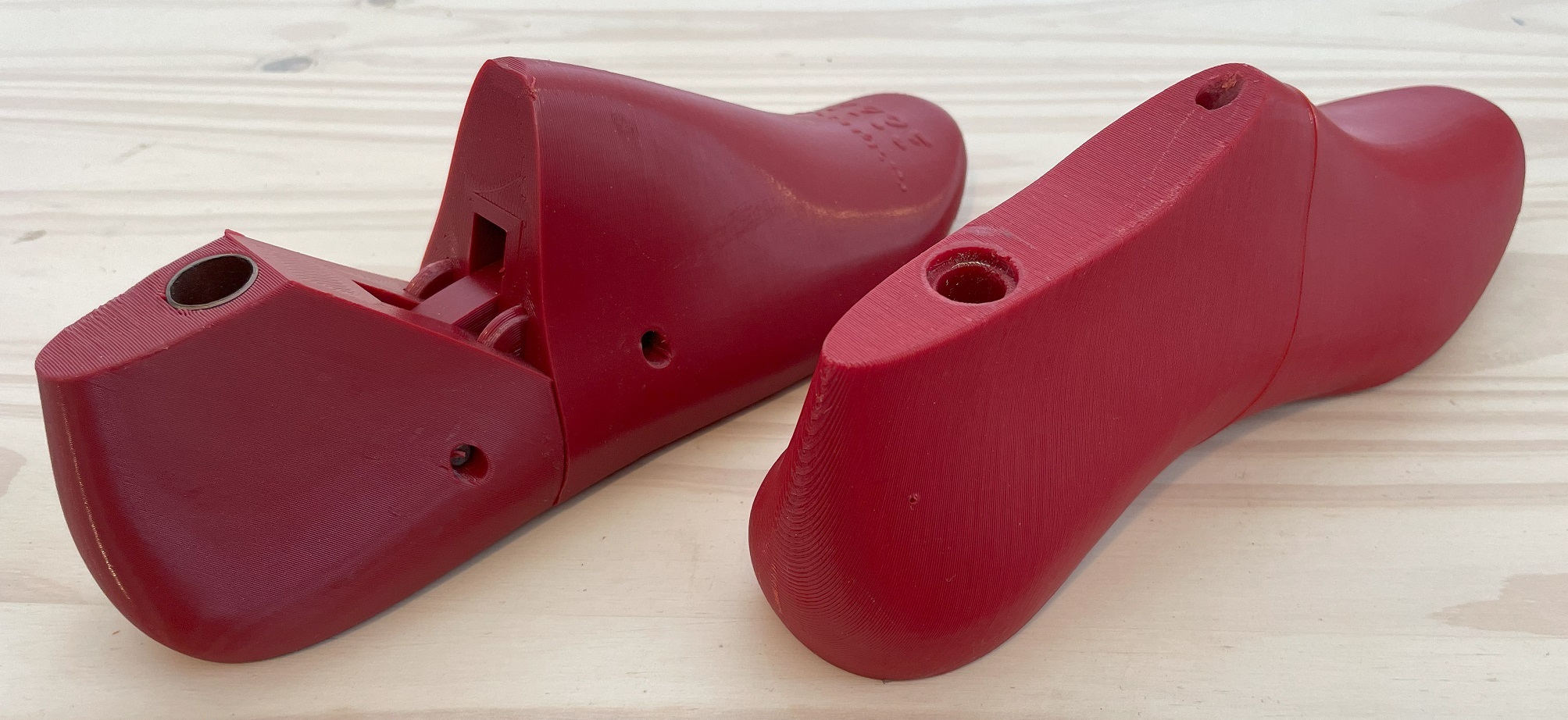

Shoe lasts can be ordered as single solid bodies or with a joint. The two types of joints available are a conventional alpha hinge and a rail joint. The rail joint with it’s smooth mechanical advantage is preferable for hobbyist shoemakers except when making closed boots like cowboy boots, in which case the alpha hinge is better. And experienced shoemakers will also find the alpha hinge more familiar.

While the shoe lasts are manufactured in North America, their light weight makes them economical for worldwide shipping. The PETG material is fully recyclable though does require a special service like Zero Waste Boxes by TerraCycle or via some 3D printing filament suppliers.

That’s all for this quick update. There will be a follow-up post getting into more depth on the various details of the ordering system for in-house designs.