The ordering system on 3DShoemaker has been developed to cater to a huge range of shoemaker needs. In this post, I’m going to explain the various possible order types and sections of the ordering form.

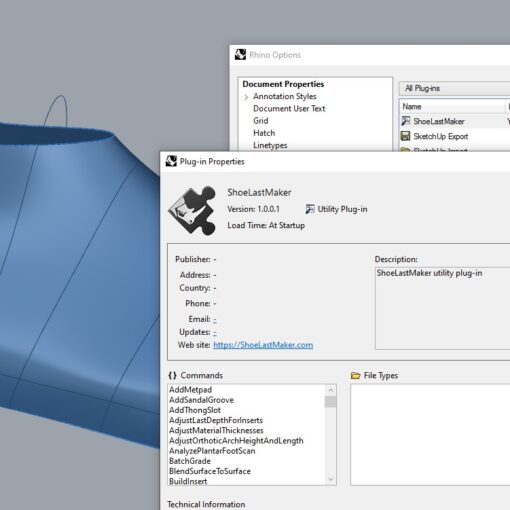

First let me say that 3DShoemaker is both the name of the website and the Rhino 3D plugin. If you are interested in the plugin, you can find out more on this page. If you are looking for shoe lasts etc., you’ll want to click on the design menu at the top of the website. From there you can can choose shoe lasts, orthotics, or components.

Shoe Last Order Types

If you choose shoe lasts from the Designs menu, you’re presented with a variety of designs to choose from. Once you choose one, you’ll be taken to the product page which contains the ordering form. On the ordering form, there is a drop down for the shoe last order type with eight options as follows:

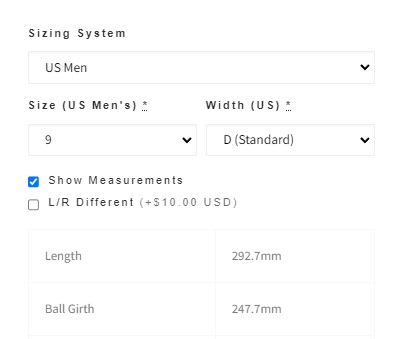

- Standard Size Print: This is the most basic order type. It is a physical shoe last of a standard size you can get shipped to you after the stated lead time (shipping prices shown at checkout). As far as sizing, you can choose the sizing system and the size and width in a section below. The corresponding measurements can be checked by clicking the ‘Show Measurements’ check box. And if you want to order different sizes for left and right feet, check the ‘L/R Different’ check box. There are some more sections with more options further down the ordering form, but they are also used for different order types, so I’ll come back to them later.

- Standard Size Model: This is basically the same as the Standard Size Print order type, except that it is a digital model that you will be emailed after the stated lead time.

- Custom Print: The Custom Print option is there for shoemakers that want to specify exact shoe last measurements rather than a specific size. Note that shoe last measurements are different from foot measurements, and coming up with them requires considerable knowledge about tolerances and allowances, so this option intended for experienced shoemakers. There are some links for those wanting to learn about allowances. But if you are a hobbyist shoemaker, it might be best to go with the Bespoke option explained later.

- Custom Model: Once again, the Model order type just means it is a 3D model of a custom shoe last that is emailed rather than a physical shoe last that is shipped.

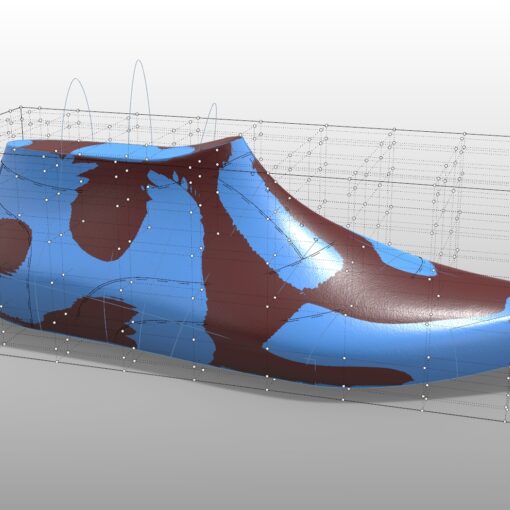

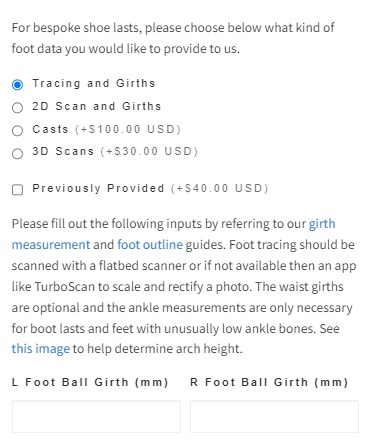

- Bespoke Print: This is the option that allows you to provide foot data in order to receive a bespoke shoe last. You’ll need to choose what type of foot data you want to provide: Tracing and Girth Measurements, 2D Foot Scan and Girth Measurements, a Cast, or a 3D Foot Scan. Depending on which of these inputs you choose to go with, you’ll be shown various fields into which you can input the necessary data along with links to various guides. Note that once you order a bespoke shoe last once, additional bespoke orders are eligible for discount by selecting the Previously Provided option.

- Bespoke Model: This is the same as Bespoke Print except you receive a 3D model by email after the stated lead time.

- Parametric Model: If you choose this option, you’ll be able to download a parametric CAD model of the selected shoe last immediately after purchase. The CAD model is in 3dm format and can be used in the 3DShoemaker plugin for Rhino 3D.

- Static Model: As with the above option, this is for a 3D model of the selected shoe last that can be downloaded immediately after purchase. But it is just a static model that comes in stl and iges formats. These formats are usable by the vast majority of CAD softwares and 3D printing slicers out there.

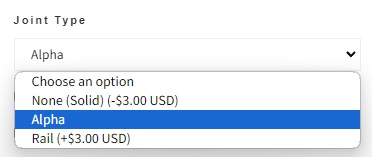

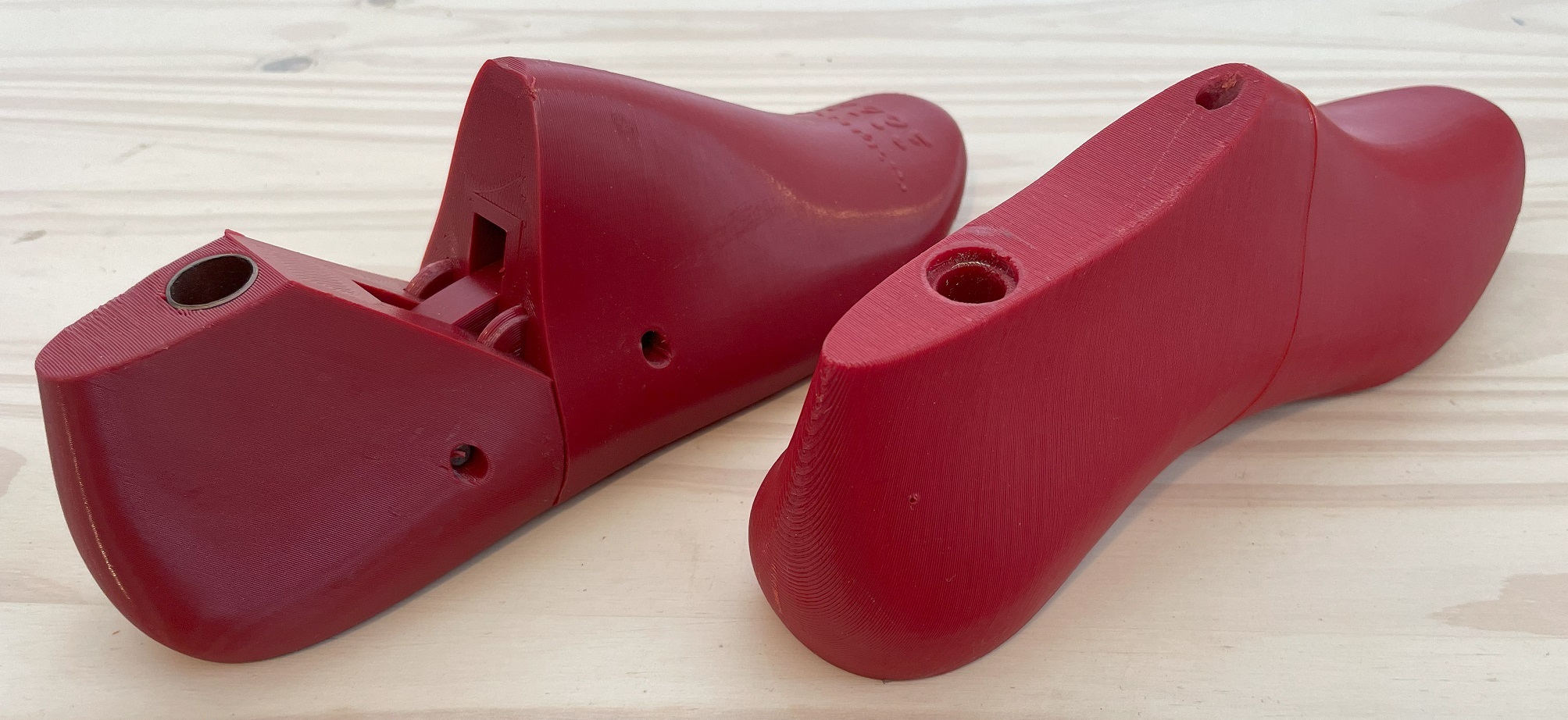

Shoe Last Joint Type

If you’ve selected one of the customizable order types (Standard Size, Custom, or Bespoke), you’ll be able to specify what kind of joint you want built into the shoe last, if any at all. A joint is necessary for removing the shoe last from most types of footwear. The rail joint is a really great option for hobbyist shoemakers given the smooth mechanical advantage of the joint. But it won’t work for closed footwear like cowboy boots. And the alpha joint will be faster to operate and more familiar to experienced shoemakers.

Shoe Last Design Adjustments

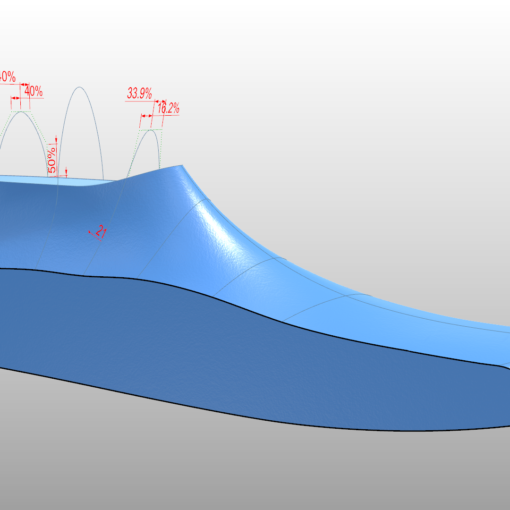

Also available for the customizable order types is Design Adjustments. If you check this box you’ll be presented with a range of possible adjustments. Most of these are self explanatory, like heel height. I’ll explain some of the less obvious options.

- Space for Insoles/Orthotics: This option allows you to essentially drop the bottom of the shoe last in order to make space for orthotics or insoles. Note that the shoe last measurements, namely the girths, also update when you use this option.

- Foot Shaped Bottom: For some types of shoe construction, the bottom of the shoe last is actually more like the top surface of an orthotic, as in it is foot shaped. If you choose this option, then you’ll need to decide what arch height you want for the foot shaped bottom.

- Feather Edge Type: Traditionally, shoe lasts have a sharp edge joining the bottom to the side walls. But some types of shoe construction, like Strobel, are better done with a filleted edge. This option allows you to specify this.

- Boot/Shoe Last Style Toggle: If you like the shoe last design you have selected but would prefer if it was a boot last rather than a shoe last (or vice versa), you can select this option. Other toggles perform simlarly as this. For instance, the Slip-On/Lace-Up toggle allows the allowances to be toggled to swap for these two fit types.

- Hanger Pull Hole: For boot construction, sometimes it is helpful to have a hole at the top and back part of the shoe last through which a metal wire can be hooked to pull the shoe last out of the boot. When you choose this option, such a hole will be designed into your shoe lasts.

- Chop Toe: Some unique toe styles can be achieved simply by cutting the end of the toe off a shoe last to create a flat plane. Use this option to achieve this on any shoe last style.

- Size Outlier: The standard sizes that can be ordered are fairly comprehensive. But if you can’t find the size you need, you can specify it here. Note there is an extra charge as outlier shoe last sizes may require additional design work and large shoe last sizes take more time and material to 3D print.

- Toe Style Change: Here you can say you want a toe style from a different shoe last in the collection swapped in for the one of the current shoe last design.

Include Patterns with the Shoe Lasts

It can be a bit tricky and time consuming to get the upper and bottom patterns copied from a shoe last. So in this section you can choose to receive these for the shoe last you are ordering. Currently they are only available as digital files (PDF or DWG), but later will be available as card stock cutouts for physical orders. Eventually there will also be detailed patterns for specific shoe types.

Include Orthotic/Insole with the Shoe Lasts

If you would like to receive orthotics or insoles with your shoe lasts, you can specify this in this section. If your order type is for a print, you will receive printed orthotics with your order, otherwise it will be a digtial model you are emailed. Various details need to be selected like the orthotic/insole type, arch height, overall depth, and top cover thickness. Note that it is recommended to attach a top cover with a soft material like Poron or EVA as the 3D printed material itself is hard. It’s particularly not suited to use without socks.

If there is some option for ordering orthotics or insoles you require that you aren’t finding on this form, you can select the complete orthotic ordering form directly via the Design menu drop down. For instance, if you want to get get it customized to a specific foot or want to order a batch, you can do it via that form.

Include Matching Components with the Shoe Lasts

This option will only be visible if there are matching components available for the shoe last you have selected. For instance, wedges with a medium heel height only show up for shoe lasts with a medium heel height. To see all available components on 3DShoemaker, check out the Design menu. By selecting individual component designs, you’ll be able to choose various customizations and also be able to order quantities.

Size Runs

If you are looking to order a size run, for instance sizes 6 through 12, you’ll need to add a shoe last to your cart for each size you are ordering. Quantity discounts get applied automatically during the checkout process. Note that if you are ordering shoe lasts with design adjustments, you’ll want to add just one size to your cart, and for the rest of the sizes, use the Developed Shoe Last on the services page. This makes it so you don’t pay for design adjustments for every size you order.

Likely this ordering system will continue to expand, and I’ll try to keep this guide updated. If you have any questions or comments, please feel free to reach out.