For many years now I’ve been wanting to try my hand at 3D printing shoes. And now that I have a new printer–the Bambu Lab X1C–with enough build volume to fit my size 14 shoes, I decided to give it a shot. I think the design I came up with has a few novel characteristics, so I decided to write about it. In same ways it worked out nicely, and in others it fell short. Let me fill you in in this 3DShoemaker post.

3D Printed Shoe with Sheet Sole

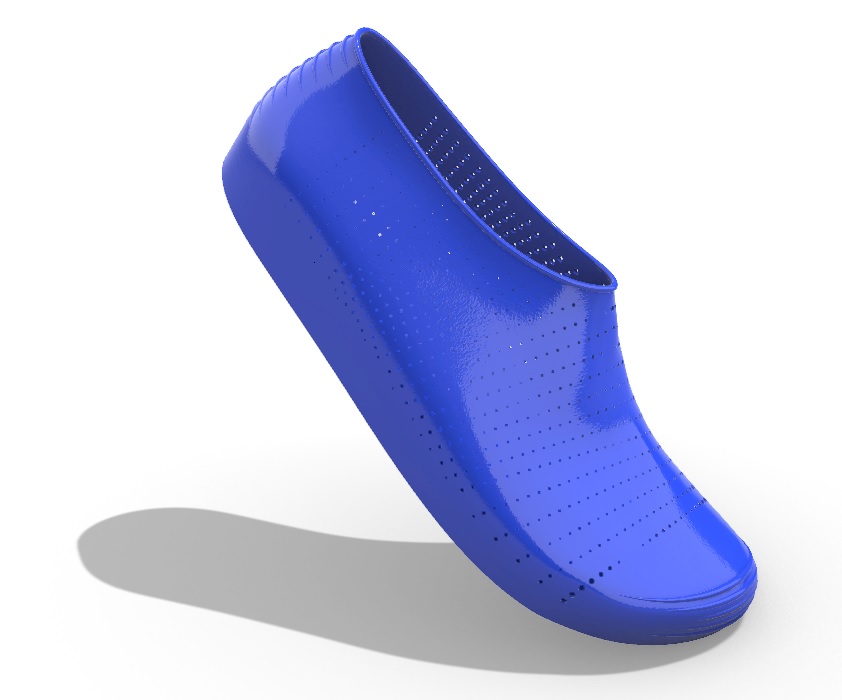

The ideal for a 3D printed shoe is for the entirety of the shoe to be 3D printed. But I decided to depart from this slightly and make the sole from an extruded sheet. This solves a couple major problems typically encountered by those 3D printing shoes on desktop 3D printers.

Firstly, it is difficult to print with filament that is as soft as shoe soles. You have to go extremely slow to avoid jams. And if you don’t want the entire shoe to be made of expensive soft filament, you’ll need a competent multi material printer, which aren’t all that common yet. So 3D printed shoes are usually made with hard outsoles that are slippery. So by using an extruded sheet for the outsole, this problem is solved. The rest of my 3D printed shoe is made with generic 95A TPU filament.

Secondly, most printers, particularly when it comes to flexible filaments, can only do single material prints. And so the print material and support material have to be the same. But removing flexible supports can be tricky and leaves behind a bit of a mess. So by having a supported surface that will later be covered by an extruded sheet, this at least covers up the aesthetics of the problem.

Toe Spring, Rocker, and other Design Characteristics for a 3D Printed Shoe

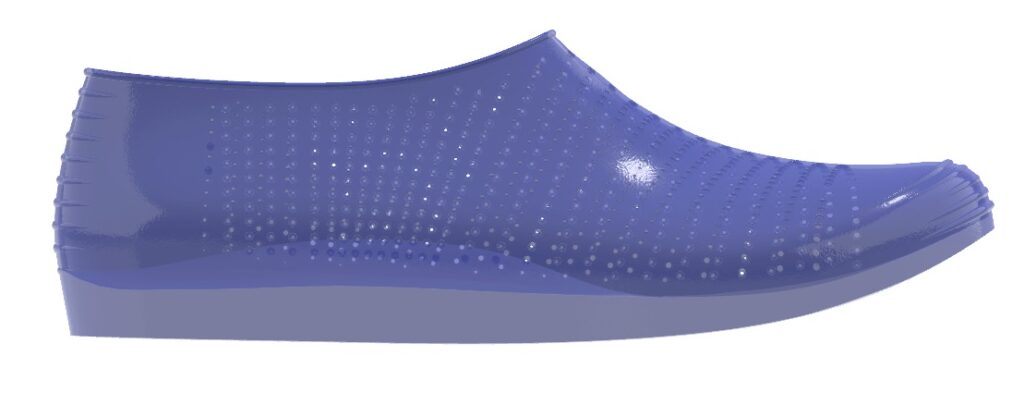

Another issue with 3D printed shoes from desktop printers is how stiff the upper is. As the ball joint articulates late in the stance phase of the gate cycle, the upper ends up folding in on itself, causing it to break down quickly and also putting pressure on the top of the ball area of the foot. The solution I used was to design in ample rocker and toe spring. So the 3D printed shoe is already built with a rolling shape in the first place.

And of course there is the issue of breathability of plastic. As with so many other 3D printed shoes out there, I simply added in lots of holes.

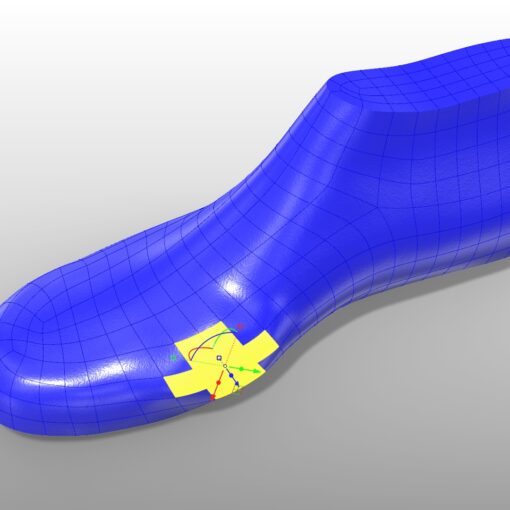

Also their is the requirement for a shock absorbing midsole which a solid print wouldn’t achieve. I simply used a 20% gyroid infill in the slicer.

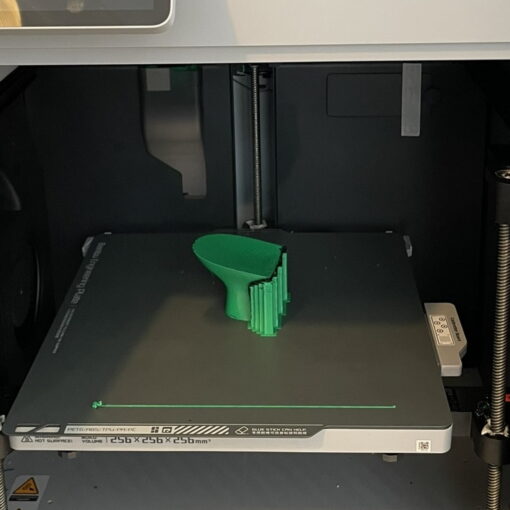

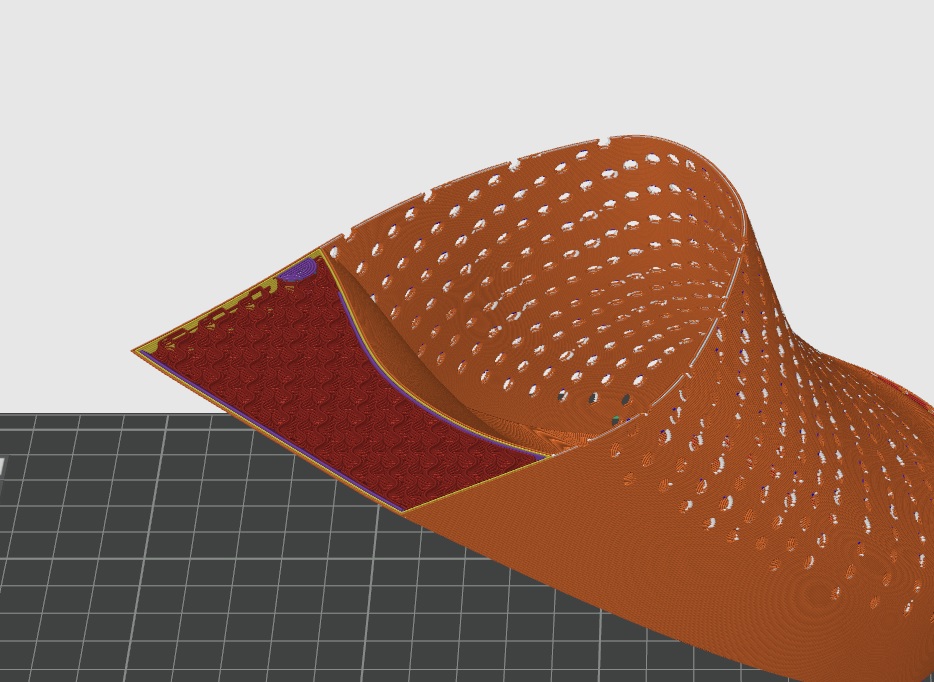

Finally, I oriented my shoe diagonally both in the vertical and horizontal planes. This allowed my US men’s size 14 shoe to just fit. The X1C has a build volume of 256mm x 256mm x 256mm which is larger than average. But even with a smaller build volume, this diagonal orientation allows for a decent sized shoe.

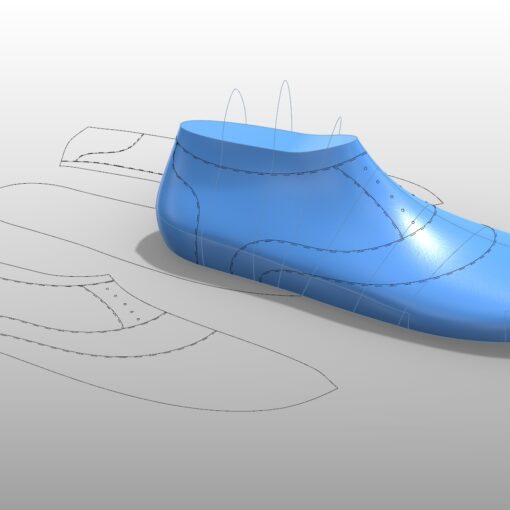

At some point I’ll give a tutorial for designing a 3D printed shoe like this. In short though, I started off with a zero drop shoe last and orthotic surface I designed in 3DShoemaker for Rhinoceros 3D. Then I used SubD and offsetting to get the outer shell followed by Boolean operations to get the actual shoe.

Results and Next Iteration

All in all, I think my 3D printed shoe worked out good as a first attempt. Using the sheet sole did address the common issues encountered exactly as I intended. That being said, I think my next 3D printed shoe iteration will be 100% 3D printed. The ideal of a shoe that requires zero manual labour to construct and is 100% recyclable is just too good.

I also need to improve on comfort and durability as my feet where chaffed a bit and the shoe broke after only a few kilometers of walking. Perhaps a lower infill but thicker walls in key areas plus higher nozzle temps for better layer adhesion will do the trick. I’ll also have to address the fit as I actually had to cut a slit to get my foot in–the material was not as stretchy as I anticipated.

This first attempt makes me better see the potential of 3D printed shoes. And I think even a basic FDM printer like the X1C will be able to create a good functional shoe. Please subscribe to see what comes next!