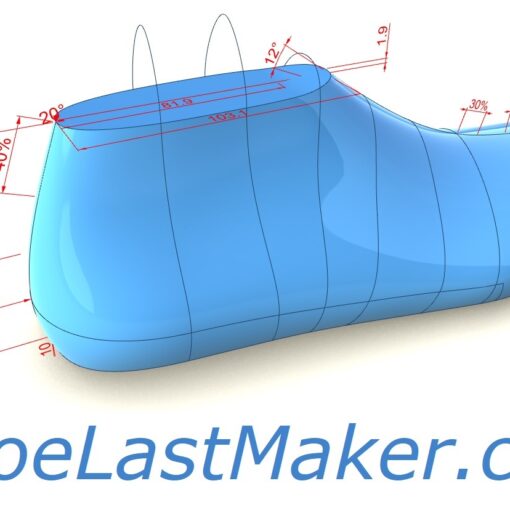

In order for a shoe built on a custom shoe last to properly fit a foot, the shoe last needs to be designed with appropriate allowances. This makes the fit snug yet gives the foot space to move in the shoe where necessary, which is crucial for proper function and comfort. This page contains some general considerations for coming up with shoe last allowances. If you’d rather we determine allowances for you, please consider a Bespoke Shoe Last instead.

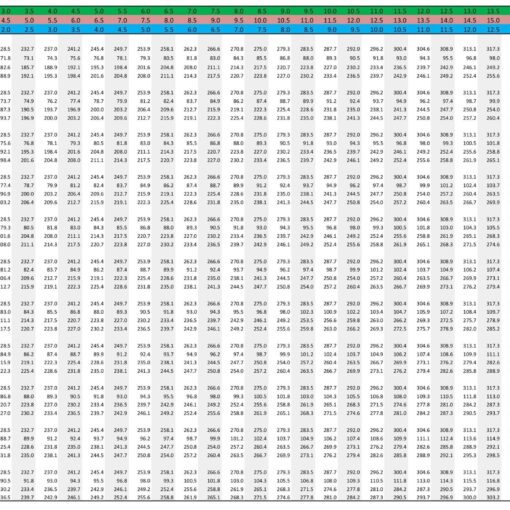

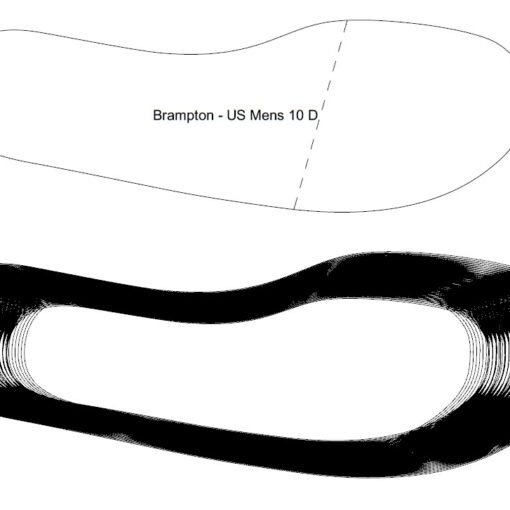

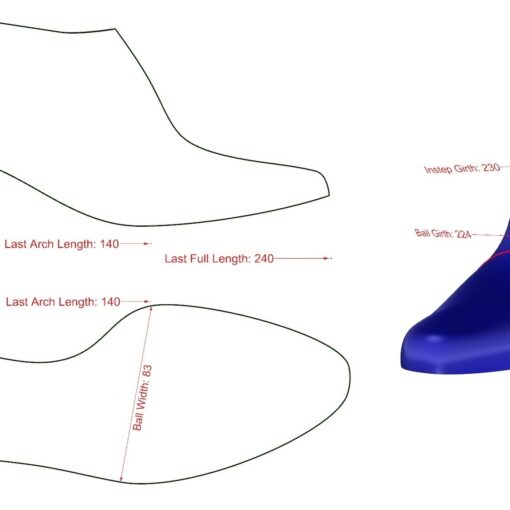

- Room to Move: First and foremost there needs to be space in front of the toes. This is because the foot lengthens and shifts in the gate cycle and space is needed to prevent the foot from butting up against the front of the shoe. Our lasts are generally 17mm longer than the length of the intended foot. This is assuming the toe shape is round. If it is a pointed toe, more space is needed. To see how much extra length we recommend for a given shoe last style, please check it’s length for the desired size and then subtract the length for the corresponding size on our sizing chart. Please keep in mind this is a very general guideline; many other factors come into play, particularly the shape of the foot.

- Sock Type: The type of sock worn can have a surprisingly large impact on the fit of a shoe, and so sock thickness has to be taken into account. Sock thickness essential increases foot length, arch length, ball and heel width, and girths, and so has to be added on to foot measurements accordingly. For general guidance, we’ve determined the thicknesses of various sock types to be:

- Nylon: 0.5mm

- Dress: 1mm

- Casual: 1.5mm

- Sport: 2mm

- Wool: 3mm

- Insert Type: All of our shoe lasts are designed to accommodate a basic 0.5mm sock lining. If anything thicker is specified in the order form, we’ll drop the last bottom accordingly. But for a custom shoe last, you’ll still want to take note of the insert thickness, as the girth measurements will have to be updated accordingly. For general guidance, we’ve determined the thicknesses of various insert types to be:

- Sock Lining: 0.5mm

- Cushioned Sock Lining: 1mm

- Footbed/Dress/Functional Orthotics: 2mm

- Accommodative Orthotics: 3mm

- Toe Style: Different shoe last toe styles can require different allowances for a given foot. For example, a pointed toe shoe last requires extra length, as the foot does not fill the pointed region. We aim to list the percentage that last length should be increased beyond our grading chart numbers in order to achieve a good fit. In the short term though, you may need to ask us for this.

- Feather Edge Compensation: Unlike a foot, shoe lasts typically have what’s called a feather edge (~90 degree corner) connecting the body of the shoe last to the bottom of the shoe last. This is critical for most approaches to shoe making. However, it results in some empty space in the resulting footwear. And so the shoe last has to be made with correspondingly larger measurements crossing these areas, namely the girths. For proper fitting footwear, appropriate feather edge allowances have to be added on to foot measurements.

- Instep Girth Fillup: Another region of empty space in the shoe is in the arch area of the foot. The amount of empty space is highly dependent on the arch height of the foot. A higher arch will have more empty space and vice versa. The instep girth measurement crosses this region and so appropriate allowances must be added on to foot measurements in order to achieve a proper fit.

- Intended Footwear Purpose: Allowances may vary depending on the intended purpose of the resulting footwear. For instance, an athletic shoe may benefit from a snugger fit on the ball width to better hold the foot during aggressive movement and yet more space in the length to ensure the toes don’t get jammed into the end during abrupt stops.

The above considerations will help you start to develop your own system for going from foot measurements to shoe last measurements. As you become more experienced, there may be other considerations you take into account, such as the elasticity of the planar fascia and amount of fatty tissue. With time and practice, you can hone your process of determining ideal custom shoe last allowances.

Next Step for Custom Shoe Lasts

Once you have measured foot girths, traced the foot, analyzed the tracing to get linear measurements, and added on allowances, you’re ready to order a custom shoe last. Visit our shoe lasts for sale page, pick a shoe last style, choose ‘Custom’ from the ‘Level of Customization’ drop down, and put in your inputs. It’s a lot of steps, we know. That’s why we made Bespoke Shoe Lasts an option too.