In this 3DShoemaker post, I’m going to demonstrate how the Vacuum Form tool can be used to adapt a shoe last to match up with a foot model while preserving toe box style and still allowing for the various post processing tools, such as 3D printable joint designs, mockup models, and morphing shoe designs. The new Vacuum Form tool should be a huge help in speeding up the design side of custom shoemaking.

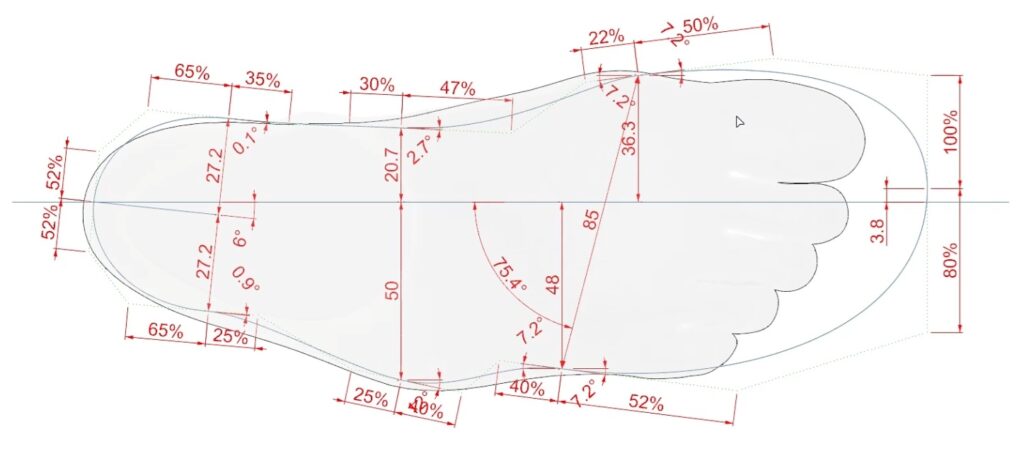

For those unfamiliar to this channel, the 3DShoemaker plugin for Rhino I wrote is, at it’s core, a parametric design system for developing primary footwear geometries, including the shoe last and footbed surfaces. This has permitted a much more scientific approach to footwear design than the various alternatives out there. But when it comes to challenging foot geometries, the foot geometry can be so irregular that the necessary parametric adjustments take too long to make or might not even provide enough control. This lead me to develop the free form sculpting tools I recently introduced. While these have been quite helpful, they can still be somewhat time consuming to use. To speed things up, I found a way to automate the use of these tools in a new feature I’ve called Vacuum Form.

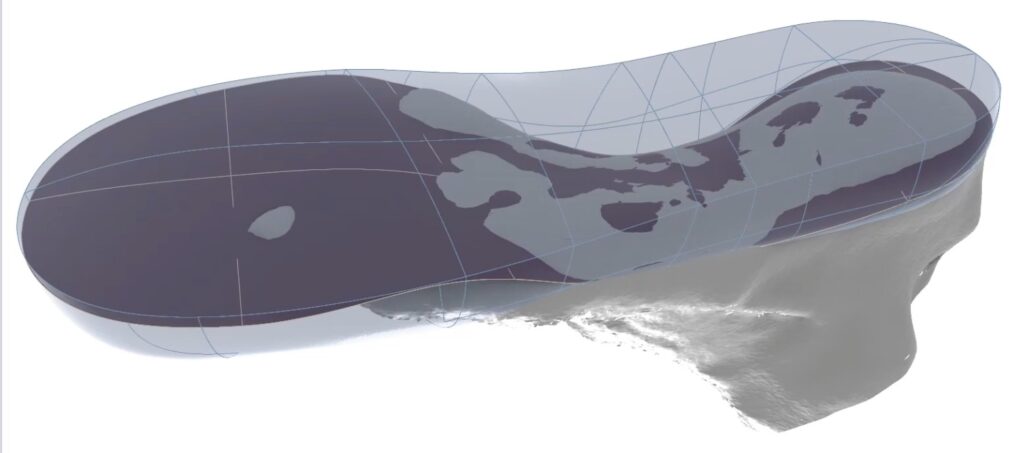

I previously demonstrated how it can be used to vacuum form insoles to plantar foot models. I’ve used the term vacuum form as that should be quite familiar to anyone who has learnt manual insole fabrication methods. In actuality though, the 3DShoemaker Vacuum Form tool is really more of a snapping of geometrical edit points to the foot model, while following certain rules to make it operate somewhat more like the real thing.

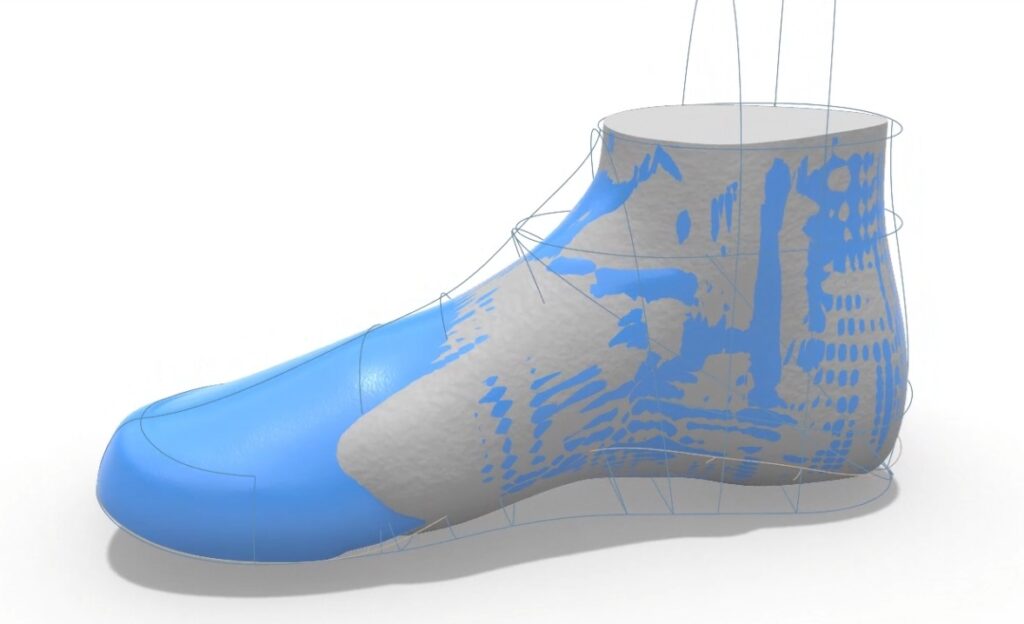

Now the idea of vacuum forming a shoe last to a foot model doesn’t have a physical twin in the real world because of course a shoe last is a bulky, solid, rigid thing. But in digital terms, their is just the surface itself. And same as with the footbed surface, the shoe last surface can be made to match the foot geometry while once again abiding to certain rules. Some of the rules are similar, such as specified offsets. One rule specific to vacuum forming of shoe lasts, a rather critical one, is the avoidance of the toe box region. The adjacent part of the foot in the toe box area is of course the toes. For the sake of maintaining a good shoe aesthetic, the tox box of the shoe last needs to be left out of the vacuum forming algorithm. In particular, the feather edge is usually maintained.

One thing I should point out is that it’s important to have a shoe last model that is reasonably close to the foot shape prior to vacuum forming. This is because large adjustments via vacuum forming can sometimes lead to undesirable results. All that is required is some basic parametric adjustments to approximately match up the shapes. It also helps to build up a library of pathology specific shoe lasts, picking the most appropriate one for any given case.

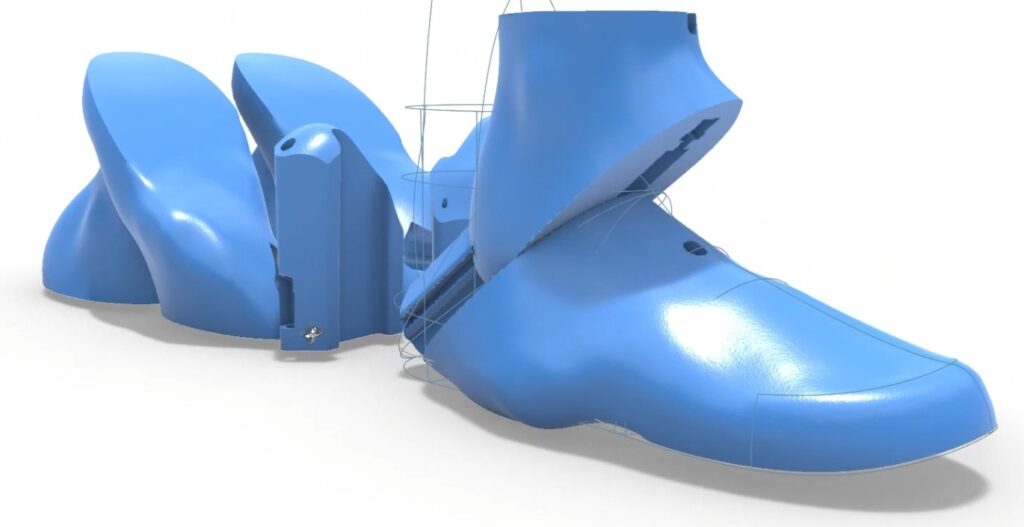

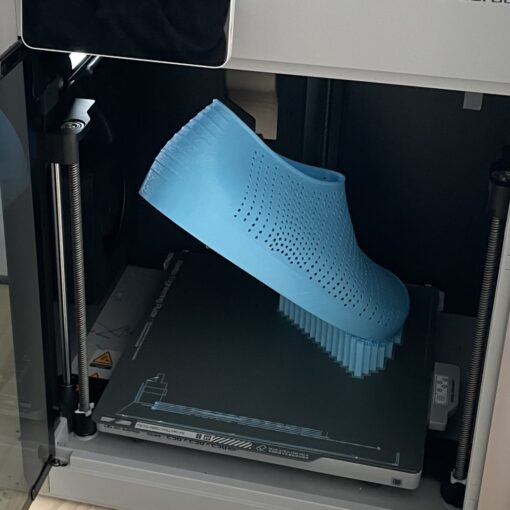

Another option that can be selected is to update the component body to follow along. This will be important to do if you plan on 3D printing a mockup prior to last and shoe manufacturing. And it is also necessary if you plan to use the morphing tool to bring over components such as cup soles or 3D printable shoe geometries to the customized shoe last. Morphing of fully 3D printable custom footwear is something I hope to get into in future updates.

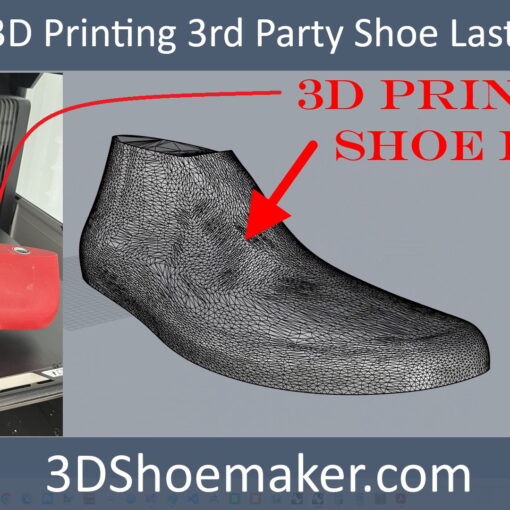

After vacuum forming, it is of course still possible to do manual sculpting to refine the design, both for the shoe last and the component body. Then once satisfied with the design, most of the various post processing features of 3DShoemaker can still be used. For instance, you may proceed with designing 3D printable joints for de-lasting. In some cases, when the shoe last is sufficiently distorted from the original parametric shape, it may be necessary to treat it as a 3rd party last via the Establish feature, which is something I’ll cover in an upcoming post.