In this 3DShoemaker video I’m going to highlight how a company called Oxman has been using 3DShoemaker to develop a special kind of shoe last for their robotically 3D printed biodegradable shoes.

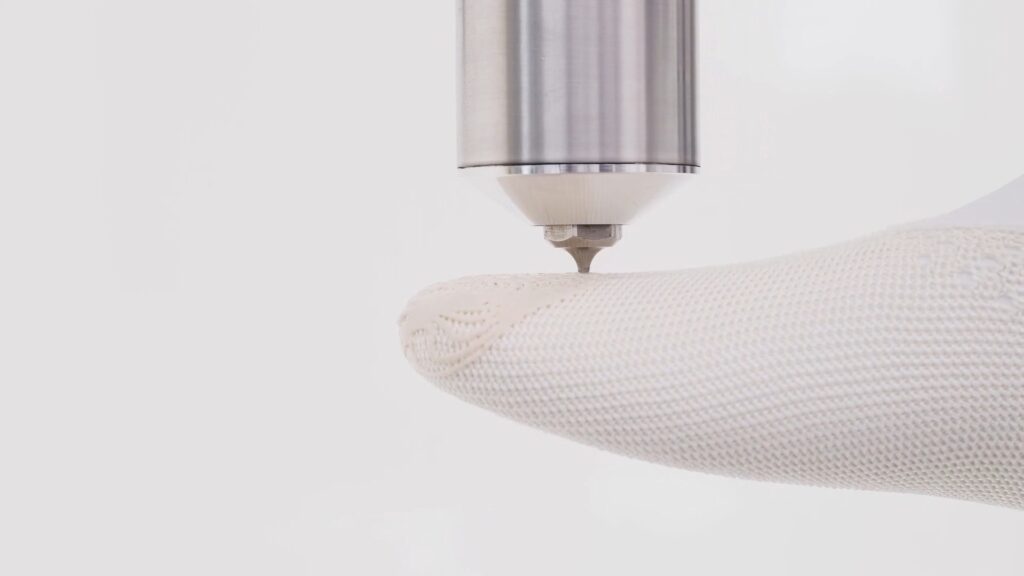

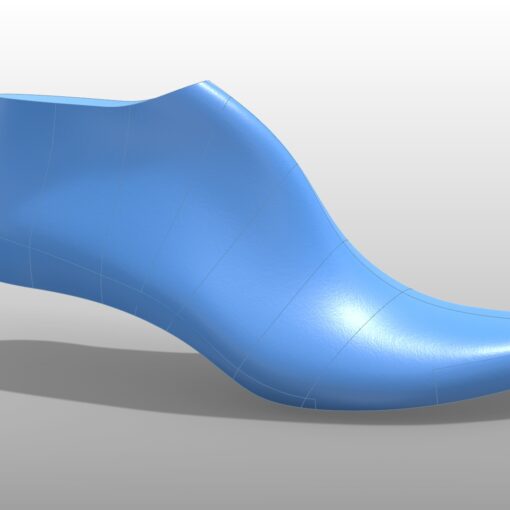

If all you have is a hammer, then everything looks like a nail. I guess that is why I go on and on about 3D printing shoes with common desktop 3D printers; because a common desktop printer is all that I have access to. But when I was approached by a company called Oxman recently, I did start thinking about the benefits of the approach they are using to 3D print shoes. Rather than printing one planar layer at a time in cartesian space, they are doing continuous printing on the surface of a physical shoe last and building outwards. Rather, it is actually a sock knitted from the same material slipped on the shoe last that they are doing the printing on. A robotic arm swivels the shoe last in space, ensuring the print head remains perpendicular to the shoe last surface at all times. It’s similar to a spherical coordinate system, but warped to the complex organic geometry of a shoe last.

A key advantage of this robotic arm approach to 3D printing shoes comes from the fact that filament is laid down tangential to the shoe last surface. The strength of the upper material then is more a function of the filament’s ability to withstand tensile stress rather than the strength of layer adhesion, which of course would be a lot less. Building out from the last is also superior for avoiding the need for support material, allowing for the focus to remain entirely on the printing of their specialty filament, which is a biodegradable filament produced from bacteria. And then there is also the unique aesthetic opportunity afforded by this particular approach to additive manufacturing. One disadvantage though is that the physical shoe last has to exist before the shoe, which is something more conventional 3D printing has helped us negate.

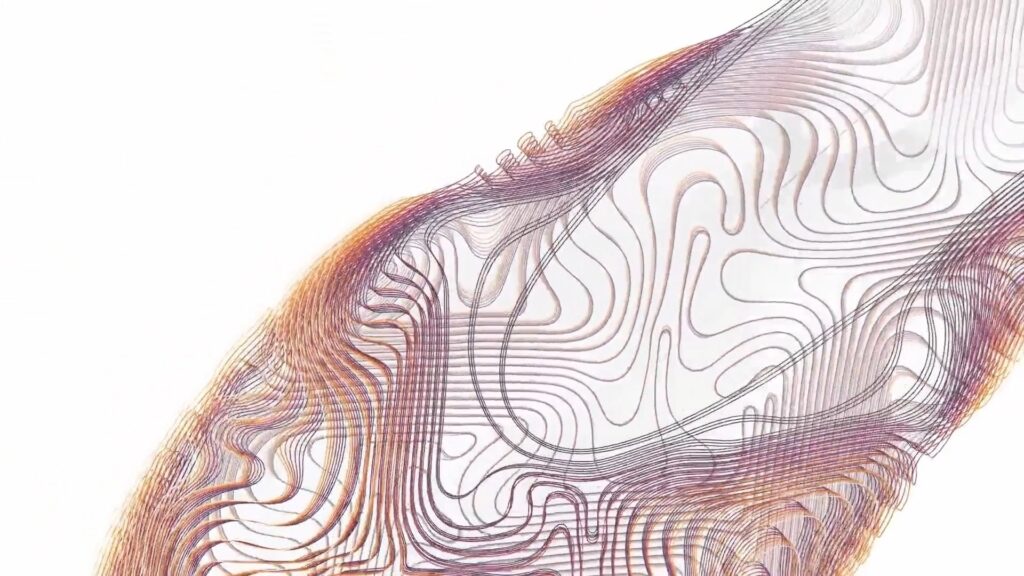

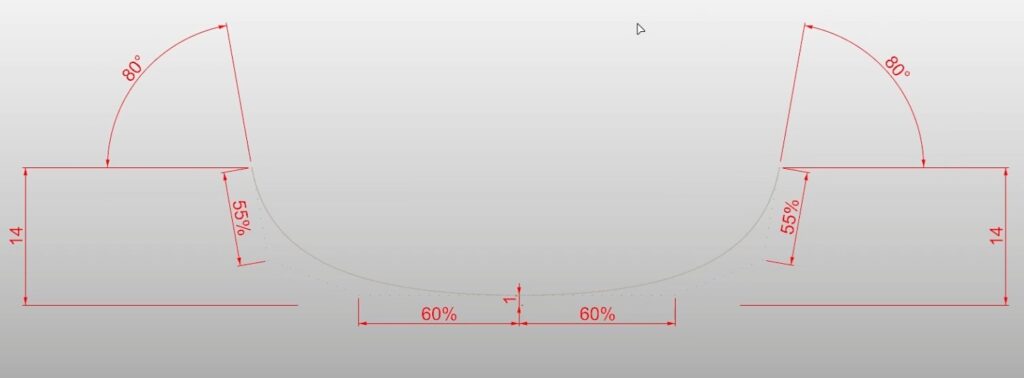

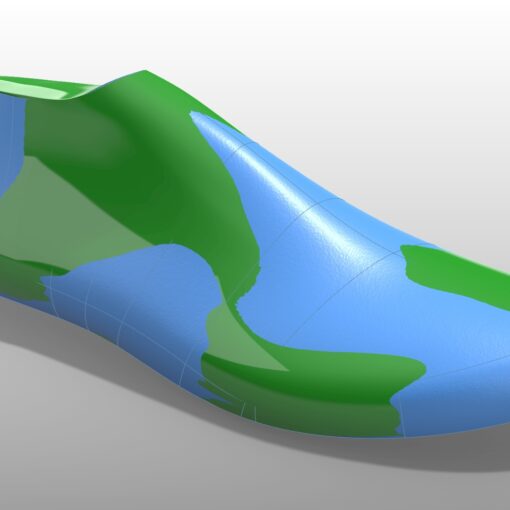

The continuous path itself is something that could be designed in Rhino as curves and then graded and customized by morphing from one shoe last to another in the 3DShoemaker plugin before converting to G-Code. But Oxman already had a solution for this. So it was mainly just the shoe lasts that Oxman developed with 3DShoemaker. The special requirement for each shoe last is that it needs to have smooth and highly continuous curvature over the entirety of the shoe last. This is to limit the accelerations required of the robotic arm as it guides the toolhead over the continuous path. So not only does the feather edge on the shoe last have to be removed, but the transition from the dorsal to the plantar part of the shoe last needs to have very gradual curvature continuity.

For anyone looking for a similar kind of shoe last, perhaps for sandal or barefoot shoemaking, a foot shaped bottom can be specified for any shoe last in the 3DShoemaker collection. Arch height can be set, and the degree of feather edge removal can be specified, including just behind the ball or the mid arch. And of course all this can be done in the 3DShoemaker plugin for Rhino 3D as well. The Build tab on the Options form is where the necessary settings can be selected. The built in footbed template can be adjusted to maximize wall to bottom continuity or a generic one can be purchased.

Getting back to Oxman, while their non-cartesian approach to 3D printing shoes has numerous advantages, it definitely takes a larger business to be able to pull it off. As for me, I will continue my own 3D shoe printing journey with conventional desktop 3D printers, partly because of my own setup, but also because of how ubiquitous and well-honed conventional desktop 3D printers are. And the way a physical shoe last isn’t required when 3D printing shoes on desktop printers makes customization more feasible, which is my own main reason for wanting to 3D print shoes. The Bambulab H2D in particular, which I posted about recently, is what I’m mainly designing for. But if biodegradable materials like those Oxman has developed could be made available for common desktop 3D printers, I would definitely be trying them out.

One last thing I would like to mention is that Oxman is currently hiring. So if any off this stuff has inspired you and you have strengths they could use, maybe consider reaching out.

That’s all for this 3DShoemaker video. If you found it interesting, please like and subscribe to the channel, and hit the bell to receive notifications of future videos. Thanks for watching.